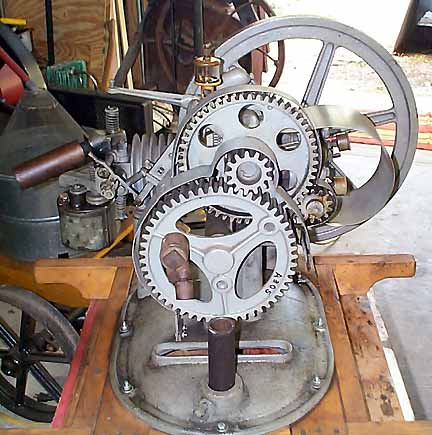

Aermotor Windmill EngineWater Pumping 8 Cycle Air Cooled Engine

The Aermotor pumping engine came on three different bases. This cast iron base pump originally cost $64 with a Webster magneto and $58 with battery ignition. In later engines, a 4-1/4" auxiliary pulley was an option for $1.50. This style of pump was desirable for use in cold climates, or where water was to be forced over a long distance from the well. This outfit was also intended for use only where there was a solid and substantial platform over the well. A long pipe and connecting rod extended down below the water table where the pump cylinder and foot valve was located.

As I've been told, the earlier and rarer engines have the "dog bone" governor and the later ones have a ball governor near the rim of the flywheel. There is a fuel check valve in the fuel can and this can be the cause of uneven running due to the varying height of fuel in the stand pipe. I had to reseat this one before it would run smoothly for any length of time. The fuel goes directly from the can into the spray nozzle and the jet is adjusted by means of a needle and seat. The inlet valve is mechanically operated by suction, otherwise known as an atmospheric valve, as ambient air pressure forces air past this valve into the combustion chamber when a vacuum is present.

The exhaust valve is mechanically operated by a valve rocker lever and is held open during hit and miss speed regulation by the governor. This same linkage also trips the ignitor at the appropriate time, just before top center on the compression stroke. There is no spark plug. A set of make and break points inside the combustion chamber first make, build up a charge in the coil and then break, flashing a spark across their contacts. Even under heavy load, this engine will fire only on every eighth cycle as determined by the cam grind and 4:1 turns ratio. This is to allow appropriate cooling of the cylinder. Intake, compression, fire, exhaust, breathe, exhaust, breathe, exhaust. Plus additional breathe and exhaust strokes as needed to govern the speed. Gasoline is taken in on the intake stroke only if the exhaust valve is closed because the extra strokes breathe in through the muffler and the open exhaust valve. For discussion about the ignition coil, see the Magneto Page.  |

This page is provided as a public service, but it is supported by your purchases

at our Old Engine bookstore. Please check it out.

Quilters: check out my wife's Quilt Shop.

There's a WHOLE LOT more to this site so click and cruise around!

| ENGINES | SHOWS | SEARCH | SUPPLIERS | IGNITIONS | ABRASIVES | CLASSIFIEDS | BOOKS |

Published by Harry F. Matthews © 1995 - 2000. ALL RIGHTS RESERVED!