Harry's OLD ENGINE #2

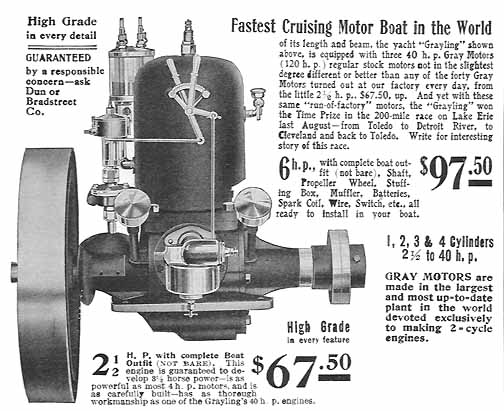

Gray Motor Company - Detroit Michigan1907 Two Cycle - Six Horsepower - Marine Gas Engine

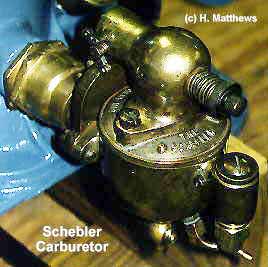

After asking a neighborhood farmer about old motors, he said, "none here, but follow me down the road to my other farm." Out behind the barn there, I saw TWO engines sitting on a wooden pallet in the burdocks! The most evident was the green open dual flywheels of a Fairbanks Z. It turned out to be a 3 HP, but the prize was what sat in front of it! A GRAY MOTOR Company of Detroit Michigan two cycle one lunger with a solid flywheel and lots of BRASS. Needless to say, we made a deal on the spot.  It is water cooled, complete with a shaft driven water pump and commutator points with lever advance. The oiler was missing and the two large grease cups were missing. Unfortunately, the spark plug was missing too so water had entered it. The good thing is that these engines had not yet spent the entire year outside in the weather. Once home, I sat the Gray on my workbench, opened it up and started soaking it with copious amounts of WD-40 and Liquid Wrench. The Fairbanks AND the Gray were both STUCK, however, patience and perseverance paid off in the long term. The Fairbanks "Z" piston came out with lots of WD-40 on both ends over a long term and then by "chucking" the flywheel back and forth. Further patience and WD-40 loosened up the two rings that were still stuck in their grooves. (The top ring was already loose.)

After achieving the 5 degrees of crank rotation, I had inserted all the grease I could find on my shelf. (Three tubes and two containers of wheel bearing grease.) Then I removed the engine base and drained away the remaining liquids. Next I hooked up the air compressor to the spark plug hole at the top, bringing up the pressure from 20 to 100 psi, but that yielded no movement. I then took a pry bar and gave lift to the underside of the rod bearing cap screw. At this point the engine was sitting in a horizontal position. KA-BLORT!!!!! Grease shot across the garage AND worse yet, my wife was standing in the doorway. She didn't get hit, but the garage floor did. This happened when the piston moved just enough to get past the 2-cycle intake port bypass inlet giving off pressure from the topside to the open crank area below. Now I was in trouble again because any pressure generated on the topside was instantly relieved to the bottom. No amount of safe force to the crank or rod was going to move this thing AND it's damned HEAVY to handle. The ONLY way to get it moving again turned out to be the reinstallation of the base and flywheel (Making it even heavier!) and chucking it back and forth. This worked! Movement! Thinking that I could then extract the rod and piston, I opened it up again. No way! So I closed it all up once again and installed the flywheel. This time I decided to roll it on through a full revolution. KA-BLORT!!!!! I never saw so damned much grease come out of one hole! Multi-colored at that. It looked like a candy cane machine as the different colors of grease had blended into a striped pattern. Well, after cleaning up that mess, I rotated the srank a few turns more for good measure and then opened it up. This time the piston was completely loose and ready for extraction. NOT! I still had to deal with the bottom side ring ridge. After getting the rings stuck on the ridge, I drove the piston back in with a wood block. This time with much more heft (I'm feeling like a weight lifter now with both ends of the crank in hand and the block, piston and rod suspended below) I gave one hell of a heave. KA-BLORT Again!!!!! And it was out! Amazingly, it looked to be in good shape. Lots of carbon, grime and remaining grease, but mechanically well. The top ring was loose, but the two others remained partially stuck in the grooves. The casting of the block is a marvel to look at. You wonder how they were able to pack sand and accomplish the water cooling passages AND the intake and exhaust passages. Much later, work progresses on the project...

So, here's where it sits now. The ultimate goal is to hear this one doing its two cycle PUTT PUTT and see it pumping water through the cooling passages. (Any day now...)

2021 ON THIS WEB SERVER:

|

There's a WHOLE LOT more to this site so click and cruise around!

| ENGINES | SHOWS | SEARCH | SUPPLIERS | IGNITIONS | ABRASIVES | CLASSIFIEDS | SMOKSTAK |

SCRAM back to Harry's

Page!

Page!Published by Harry Matthews © 1995 - 2021. ALL RIGHTS RESERVED!

The Gray Motor's piston came out later. I had been able to get about 5 degrees worth of crank rotation by using the grease gun method. (Pressurizing the combustion chamber by inserting grease through the sparkplug hole.) This was after about a two week internal soaking with a mixture of kerosene, toulene, and xylene. Keep in mind that this engine does not have a removable head for access to the piston crown. I should have made a video of this whole procedure because the GREASE GUN and OIL method had some hilarious results.

The Gray Motor's piston came out later. I had been able to get about 5 degrees worth of crank rotation by using the grease gun method. (Pressurizing the combustion chamber by inserting grease through the sparkplug hole.) This was after about a two week internal soaking with a mixture of kerosene, toulene, and xylene. Keep in mind that this engine does not have a removable head for access to the piston crown. I should have made a video of this whole procedure because the GREASE GUN and OIL method had some hilarious results.

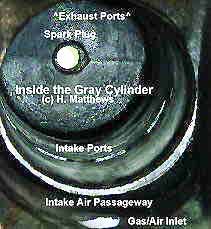

When the piston reaches the bottom of its travel, the ports are uncovered, at which time the pressurized charge of new fuel and air is allowed to travel up and into the cylinder. The piston has a special crown shape so as to allow the inrush of air/fuel mix to blow (scavenge) the spent air up, over and out the exhaust ports. This exhaust is then piped on out where spent cooling water from the head is injected into the exhaust pipe, which keeps the exhaust pipe cool.

When the piston reaches the bottom of its travel, the ports are uncovered, at which time the pressurized charge of new fuel and air is allowed to travel up and into the cylinder. The piston has a special crown shape so as to allow the inrush of air/fuel mix to blow (scavenge) the spent air up, over and out the exhaust ports. This exhaust is then piped on out where spent cooling water from the head is injected into the exhaust pipe, which keeps the exhaust pipe cool.

A

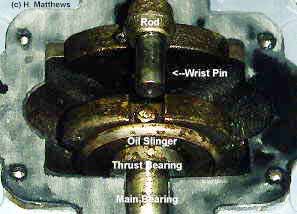

A  You can mix oil with the fuel as with other 2 cycle engines, but a dual oiler is provided, one outlet for the ring area and the other feeds a slinger on the crank. This slinger is ported to the rod bearing with a passageway inside the crank pin. Oil is not desirable in the base of this engine and therefore a blow-off cock is provided to drain the base while it is running.

You can mix oil with the fuel as with other 2 cycle engines, but a dual oiler is provided, one outlet for the ring area and the other feeds a slinger on the crank. This slinger is ported to the rod bearing with a passageway inside the crank pin. Oil is not desirable in the base of this engine and therefore a blow-off cock is provided to drain the base while it is running.